Plastics are everywhere in our daily lives and there are types of plastic. From the water bottle you drink in the morning to the car you drive to work, plastics play a significant role in our world. But have you ever stopped to think about the different types of plastics and their various applications?

Plastics can be divided into several categories, each with its own properties and uses. Polyethene, polypropylene, polyvinyl chloride, polystyrene, polyethene terephthalate, and polycarbonate are just a few examples of the many different types of plastics available.

Each type of plastic has its unique characteristics that make it suitable for specific applications. For example, polyethene is often used in packaging and toys because of its flexibility, while polycarbonate is used in electronic components and eye protection because of its strength and transparency.

In this blog, we will explore the different types of plastic, their applications, and the advantages and disadvantages of using plastics. By gaining a better understanding of the different types of plastics, we can make informed decisions about the products we use and the impact they have on the environment.

Polythene (PE)

Polyethene (PE) is one of the most commonly used plastics in the world, and it has a wide range of applications. It is known for its flexibility and low cost, making it a popular choice in industries such as packaging, toys, and containers. PE is also lightweight and durable, making it ideal for products that need to be transported or handled frequently.

PE is available in several forms, including low-density polyethene (LDPE), linear low-density polyethene (LLDPE), and high-density polyethene (HDPE). LDPE is known for its flexibility, while HDPE is known for its strength and rigidity. LLDPE is a hybrid of LDPE and HDPE and is often used in products that require both flexibility and strength.

In the packaging industry, PE is used to make plastic bags, food packaging, and disposable cutlery. In the toy industry, PE is used to make action figures, dolls, and other playthings. PE is also commonly used in the construction industry to make pipes and fittings for water and gas distribution. This is the most popular types of plastic.

Polypropylene (PP)

Polypropylene (PP) is another widely used plastic that has a range of properties and applications. It is known for its toughness and durability, making it a popular choice in industries such as car parts, packaging, and textiles. PP is also resistant to moisture and chemicals, making it ideal for products that are exposed to harsh environments.

PP is available in several forms, including homopolymer polypropylene and copolymer polypropylene. Homopolymer polypropylene is known for its stiffness and high melting point, while copolymer polypropylene has improved impact resistance and toughness.

In the automotive industry, PP is used to make car parts such as bumpers, battery cases, and fuel tanks. The Packaging industry uses PP used to make containers, films, and bags. In the textiles industry, PP is used to make non-woven fabrics, such as carpet backing and upholstery.

Polyvinyl Chloride (PVC)

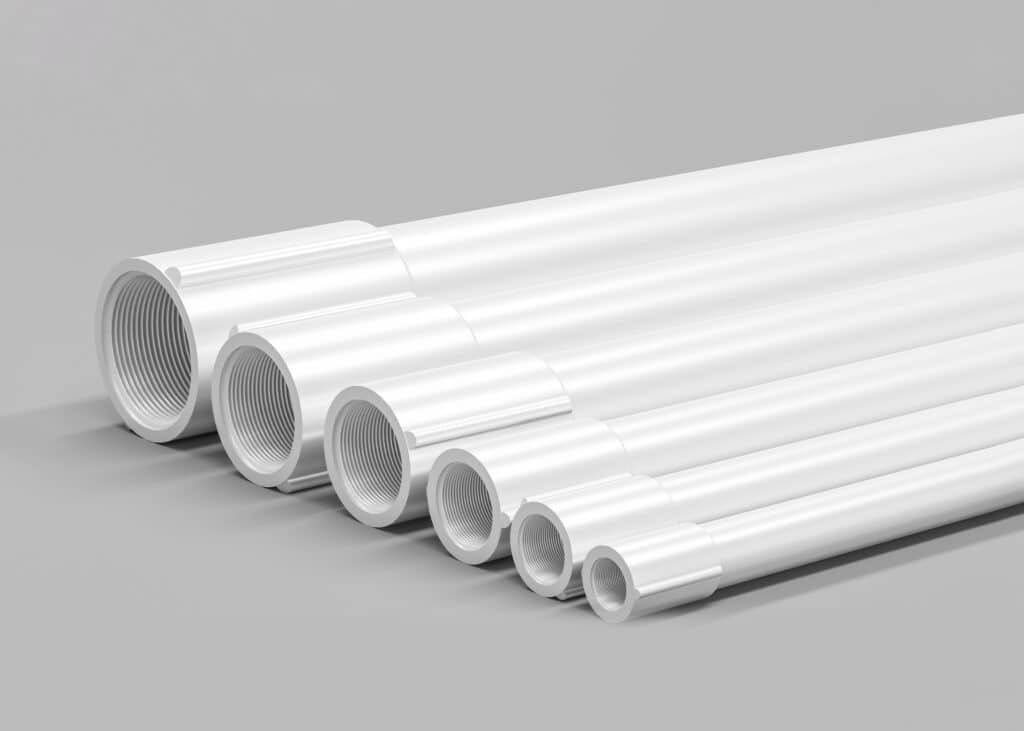

Polyvinyl Chloride (PVC) is a popular plastic for its strength, durability, and versatility. It is widely used in construction, electrical, and plumbing industries for applications such as pipes, window frames, and electrical cable insulation.

PVC is a thermoplastic material that is easy to process and manipulate, making it a popular choice for applications that require bending, welding, or glueing. It is also resistant to moisture, chemicals, and fire, making it ideal for products that are exposed to harsh environments.

In the construction industry, PVC is used to make water and waste management pipes, as well as window frames and door frames. The electrical industry uses PVC used as insulation for electrical cables and wires. In the plumbing industry, PVC is used to make pipes and fittings for hot and cold water systems. PVC is a widely used types of plastic across the world.

Polystyrene (PS)

Polystyrene (PS) is a popular plastic that is known for its lightweight and insulation properties. It is widely used in the packaging, construction, and consumer goods industries for applications such as foam packaging, insulation, and disposable tableware.

PS is a thermoplastic material that is easy to process and shape. Making it a popular choice for applications that require rigidity and durability. It is also moisture-resistant, making it ideal for products that need to be protected from moisture and humidity.

In the packaging industry, PS is used to make foam packaging for electronics, furniture, and other fragile items. The construction industry uses PS as insulation for walls, roofs, and floors. In the consumer goods industry, PS is used to make disposable tableware, such as plates and cups.

Polyethylene Terephthalate (PET)

Polyethylene Terephthalate (PET) is a popular plastic known for its strength, transparency, and resistance to moisture. It is widely used in the packaging, food, and beverage industries for applications such as bottles, containers, and packaging films.

PET is a thermoplastic material that is easy to process and shape. Making it a popular choice for applications that require transparency and clarity. It is also lightweight, making it ideal for products that need to be transported or handled frequently.

In the packaging industry, PET is used to make bottles for beverages, such as water and soda. As well as containers for food and personal care products. The food industry uses PET to make packaging films for fresh produce, such as fruits and vegetables. In the beverage industry, PET is used to make bottles for juices, teas, and other beverages.

Polycarbonate (PC)

Polycarbonate (PC) is a type of plastic that is known for its strength, transparency, and resistance to impact. It is widely used in the construction, electrical, and consumer goods industries for applications. Such as safety glasses, compact discs, and electrical components.

PC is a thermoplastic material that is easy to process and shape. Making it a popular choice for applications that require transparency and toughness. It is also resistant to moisture and UV light, making it ideal for products that are exposed to harsh environments.

In the construction industry, PC is used to make safety glasses, skylights, and greenhouses. The electrical industry uses PC as a material for electrical components, such as circuit breaker panels and electrical enclosures. In the consumer goods industry, PC is used to make compact discs, digital versatile discs, and other optical storage media.

In conclusion, plastics play a crucial role in many industries and are used for a wide range of applications. Each of the types of plastic has its own unique properties and characteristics, making it ideal for specific uses. From the versatile Polyvinyl Chloride (PVC) used in construction and electrical industries to the lightweight Polystyrene (PS) used in packaging and consumer goods, to the transparent and impact-resistant Polycarbonate (PC) used in construction and electrical industries, each type of plastic has something to offer.

It is important to consider the properties of each type of plastic when selecting a material for a specific application, as the right plastic can provide the necessary strength, durability, and performance to meet the requirements of the product. Understanding the properties and applications of different types of plastic is crucial for making informed decisions in the design, production, and use of products made from these materials.